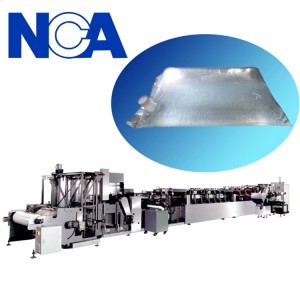

NCA1604C Flexible Pouch and Spout Automatic Sealing Machine

Usage

l.The machine is used to weld a plastic spout to a flexible pouch.

2.It is suitable for a slightly larger packaging drinks, jelly, soy sauce, flavorings and cosmetics (milk, face mask) etc..

Advantage

1. 3 servo mechanical sealing, little noise, and low gas consumption

2. Different functions: center/corner spout pouch; 60-70 pieces per minute

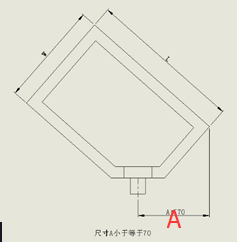

3. Center spout pouch dimensions: 230*180mm; 230*150mm corner spout pouch.

4. Improvements to the safety protective cover

5. Pouch holder design that is exactly positioned

6. Improved pouch placement, more stable and easy to adjust

Main Technical Specification